A hydraulic baling press is an industrial machine designed to compress loose, bulky materials into compact, dense bales using hydraulic pressure. These bales are easier to store, transport, recycle, or dispose of, helping industries reduce handling costs and improve operational efficiency.

Hydraulic baling presses are widely used for materials that occupy large volumes but have low weight, such as paper, plastic, textile waste, and packaging scrap.

Choosing the correct baler orientation (vertical or horizontal) is critical for:

An incorrect choice can lead to inefficiencies, higher labor costs, and limited scalability, while the right baler improves productivity and return on investment.

Hydraulic baling presses are essential across multiple sectors, including:

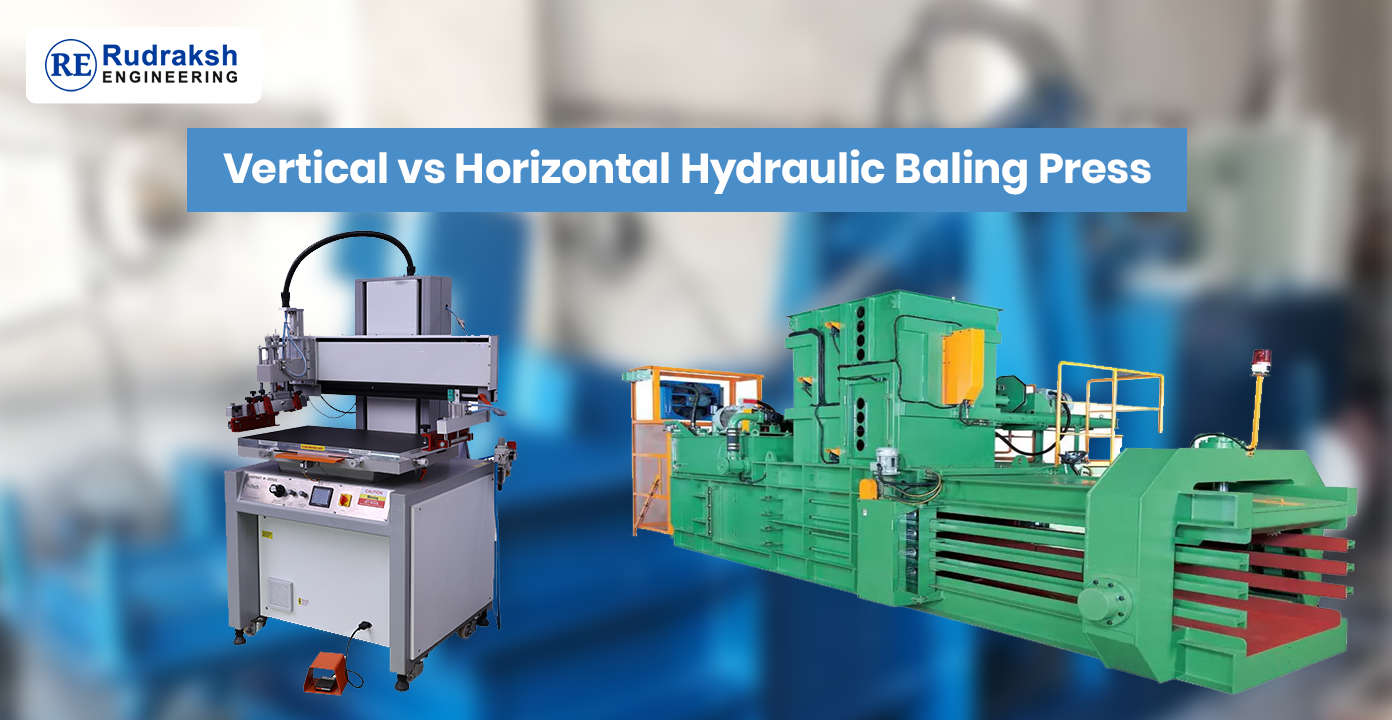

A vertical hydraulic baling press is a compact baler where material is loaded manually from the front or top, and compression occurs in a vertical downward direction. These machines are ideal for low to medium-waste generation facilities.

Material is manually placed into the baling chamber. A hydraulic cylinder pushes the platen downward, compressing the material layer by layer. Once the desired compression is achieved, the bale is tied manually using wires or straps and ejected from the chamber.

Compact and Space-Saving

Ideal for facilities with limited floor space such as shops, warehouses, and small factories.

Lower Initial Cost

More affordable compared to horizontal balers, making them suitable for startups and small businesses.

Easy Installation and Operation

Requires minimal setup, lower power consumption, and basic operator training.

Lower Output Capacity

Not suitable for high-volume or continuous waste generation.

Manual or Semi-Automatic Operation

Higher dependency on labor for loading, tying, and unloading bales.

Not Ideal for Continuous Production

Best suited for batch processing rather than nonstop industrial operations.

A horizontal hydraulic baling press is designed for high-volume, continuous waste processing. Material is fed horizontally, either manually or through conveyors and automated feeding systems, making it ideal for large-scale industrial applications.

Material is fed into the baler chamber continuously.

A horizontal hydraulic ram compresses the material sideways into uniform bales.

Once compressed, the bale is automatically tied and discharged, allowing uninterrupted operation.

These features significantly reduce labor involvement and improve productivity.

High Output and Continuous Operation

Designed for round-the-clock processing of large waste volumes.

Fully or Semi-Automatic Options

Reduces manpower requirements and improves workplace safety.

Uniform Bale Density

Produces consistent, export-quality bales that are easier to transport and sell.

Higher Capital Investment

Initial purchase cost is significantly higher than vertical balers.

Requires More Floor Space

Needs adequate installation area, including feeding and discharge zones.

Higher Maintenance Cost

More components, automation, and hydraulics lead to increased maintenance requirements.

Both vertical and horizontal hydraulic baling presses serve the same core purpose—compressing waste into compact bales—but their design, performance, and applications differ significantly. Understanding these differences is essential for selecting the most efficient solution.

| Parameter | Vertical Hydraulic Baling Press | Horizontal Hydraulic Baling Press |

|---|---|---|

| Orientation & Design | Vertical compression with downward pressing platen | Horizontal compression with side-pushing ram |

| Bale Output Capacity | Low to medium output; batch processing | High output; continuous processing |

| Automation Level | Manual or semi-automatic | Semi-automatic or fully automatic |

| Space Requirement | Compact footprint; suitable for limited spaces | Requires larger floor area for feeding and discharge |

| Power Consumption | Lower power usage | Higher power due to automation and continuous operation |

| Labour Requirement | Higher manpower involvement | Minimal labour due to automation |

| Cost Comparison | Lower initial investment | Higher capital investment |

Choosing between a vertical or horizontal baling press largely depends on waste volume, production continuity, and industry type.

Best Choice: Vertical Hydraulic Baling Press

Vertical balers are ideal for warehouses, retail stores, godowns, and small recycling units where waste accumulation is periodic rather than continuous.

Best Choice: Horizontal Hydraulic Baling Press

Horizontal balers are widely used in large recycling facilities and municipal waste plants where productivity and speed are critical.

Best Choice: Horizontal Hydraulic Baling Press

Horizontal balers help manufacturers reduce downtime, labour dependency, and waste handling costs.

Choice Depends on Scale

For continuous cotton waste, yarn, or plastic scrap generation, horizontal balers provide better efficiency and consistency.

Understanding both initial costs and long-term operational expenses is vital before purchasing a hydraulic baling press.

In high-output facilities, horizontal balers often deliver better long-term value despite higher initial costs.

Selecting the right hydraulic baling press requires evaluating operational needs, space, and future growth plans.

If your business prioritizes low investment and space efficiency, a vertical hydraulic baling press is the right choice.

If your focus is high productivity, automation, and long-term savings, a horizontal hydraulic baling press delivers superior performance.

Before investing in a hydraulic baling press, buyers should evaluate both technical specifications and long-term operational support. This checklist helps avoid costly mistakes and ensures optimal performance.

Pressing force determines how dense and stable the bale will be.

Choosing insufficient tonnage results in loose bales and lower resale value.

Proper power planning prevents downtime and electrical issues.

Essential safety components include:

Advanced safety features are particularly critical for automated horizontal balers.

Reliable after-sales service is crucial for industrial machines.

Strong after-sales support ensures longer machine life and consistent performance.

Small Businesses & Startups

Medium to Large Businesses

For small to medium cardboard waste, a vertical baling press is sufficient.

For large, continuous cardboard waste, a horizontal baler offers better efficiency and uniform bale density.

Yes, for high-volume operations. Although the initial cost is higher, labour savings, faster processing, and higher bale resale value make horizontal balers cost-effective in the long run.

Actual consumption varies by material type and operating hours.

With proper maintenance:

Machine lifespan largely depends on usage intensity and service quality.

Investing in a hydraulic baling press is a long-term operational decision, not just a one-time purchase.

Selecting a baler that aligns with:

ensures maximum efficiency and cost savings.

Businesses should also consider:

Choosing a scalable baling press today helps avoid early replacement costs tomorrow.

A vertical hydraulic baling press is ideal for compact, budget-conscious operations, while a horizontal hydraulic baling press delivers unmatched performance for high-volume, industrial applications. The smartest choice balances current needs with future growth.

Rudraksh Engineering was established in 2007 with a clear vision to deliver reliable, high-performance industrial machinery that meets the evolving needs of the manufacturing sector. Since our inception, we have remained committed to providing quality-driven, durable, and technologically advanced solutions to our clients.

Based in Rajkot, Gujarat (India)—a prominent hub for engineering and manufacturing—we have developed strong expertise in designing and supplying a wide range of sheet metal and fabrication machinery. Our consistent focus on innovation, precision engineering, and customer satisfaction has helped us build a trusted name in the industry.

We are engaged in manufacturing and supplying a comprehensive range of industrial machines, including:

All our machines are manufactured using high-quality raw materials and advanced production techniques, ensuring superior performance, operational safety, and long service life.

At Rudraksh Engineering, quality is the foundation of everything we do. Each machine undergoes strict quality checks at every stage of production to ensure accuracy, durability, and efficiency. Our products are designed to deliver consistent output, low maintenance, and high productivity, even under demanding industrial conditions.

We continuously strive to improve our products and processes by adopting new technologies and customer-focused innovations. Our goal is to build long-term relationships with clients by delivering machines that add real value to their operations.