Press brakes play a critical role in sheet metal fabrication by enabling precise bending and forming of metal sheets into required shapes. From small workshops to large-scale manufacturing units, press brakes are essential for producing components used in automotive, construction, electrical, and industrial machinery sectors.

Choosing the right press brake technology directly impacts productivity, bending accuracy, operational cost, and long-term efficiency. An unsuitable machine can lead to inconsistent bends, higher maintenance expenses, and reduced output, while the right choice improves turnaround time and product quality.

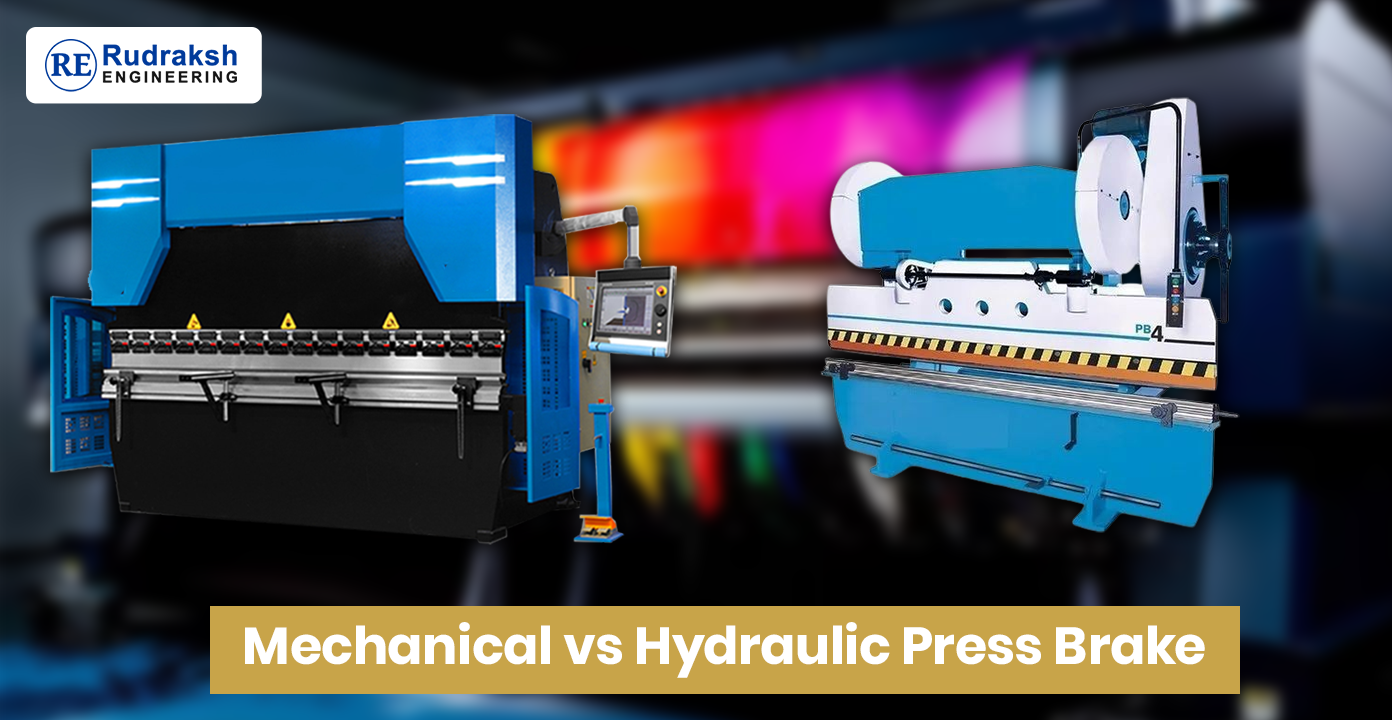

Among the most commonly used options, mechanical press brakes and hydraulic press brakes differ significantly in working principle, performance, and application suitability. Understanding these differences helps manufacturers select the ideal solution for their fabrication needs.

A mechanical press brake is a traditional sheet metal bending machine that operates using a mechanical drive system. It relies on stored kinetic energy to apply force during the bending process, making it suitable for high-speed operations.

Mechanical press brakes use a flywheel powered by an electric motor, which stores rotational energy. This energy is transferred through a clutch, crankshaft, and connecting rods to move the ram downward and perform the bending operation. Once engaged, the stroke is fixed and completes a full cycle.

Mechanical press brakes are widely used in fabrication units where repetitive, high-volume bending is required, such as appliance manufacturing, metal furniture production, and standard sheet metal components.

A hydraulic press brake uses hydraulic pressure to apply controlled force for bending sheet metal. It is designed for precision, flexibility, and handling varied bending requirements.

Hydraulic press brakes operate using hydraulic cylinders filled with pressurized oil, which drive the ram movement. Pressure, stroke length, and bending force can be accurately controlled through hydraulic valves and CNC or NC control systems.

Hydraulic press brakes are widely used in industries requiring complex bends, variable thickness handling, and high accuracy, including automotive, aerospace, heavy engineering, and custom fabrication workshops.

Understanding the core differences between mechanical and hydraulic press brakes helps fabrication units choose the right machine based on production volume, precision needs, and operational flexibility.

Mechanical press brakes operate with a fixed bending force, determined by the flywheel and crank mechanism. Once the stroke begins, force delivery cannot be adjusted mid-cycle, making them suitable mainly for uniform jobs.

Hydraulic press brakes, on the other hand, offer fully adjustable bending force. Operators can precisely control pressure based on material thickness and bend complexity, ensuring consistent results across varied applications.

Mechanical press brakes are known for their faster cycle times, making them ideal for repetitive, high-speed bending operations.

Hydraulic press brakes operate at a moderate speed, but compensate with better control, smoother motion, and flexibility for complex bends.

Mechanical press brakes provide moderate accuracy, which may vary due to wear in mechanical components over time.

Hydraulic press brakes deliver high accuracy and repeatability, especially when equipped with CNC or NC controllers, making them suitable for precision fabrication.

Mechanical press brakes tend to have lower energy efficiency as the flywheel runs continuously, consuming power even during idle time.

Hydraulic press brakes are more energy-efficient, as power is consumed only when hydraulic pressure is required for bending operations.

Mechanical press brakes experience higher wear and tear due to continuous mechanical motion, increasing maintenance frequency.

Hydraulic press brakes feature easier and more predictable maintenance, mainly involving hydraulic oil checks and seal replacements.

Mechanical press brakes offer limited automation compatibility, restricting their use in advanced fabrication setups.

Hydraulic press brakes are fully compatible with CNC and NC automation, enabling programmable bending sequences, reduced manual intervention, and higher productivity.

|

|

Mechanical Press Brake | Hydraulic Press Brake |

|---|---|---|

| Bending Force Control | Fixed | Adjustable |

| Speed | Faster | Moderate |

| Accuracy | Moderate | High |

| Energy Efficiency | Lower | Higher |

| Maintenance | Higher Wear | Easier Maintenance |

| Automation Support | Limited | CNC / NC Compatible |

Mechanical press brakes excel in mass production environments where the same bending operation is repeated continuously. Their faster stroke speed improves output for standardized components.

Hydraulic press brakes are better suited for medium to high-mix production, where job variation, setup changes, and precision are more important than raw speed.

In applications demanding tight tolerances and consistent angles, hydraulic press brakes outperform mechanical models. CNC-controlled systems ensure repeatability even across large production batches.

Mechanical press brakes may show variation over time due to mechanical wear, especially in high-load operations.

Mechanical press brakes have limited load-handling flexibility and are best for light to medium sheet thicknesses.

Hydraulic press brakes handle wider thickness ranges and higher tonnage, making them suitable for heavy-duty fabrication and thick metal plates.

Mechanical press brakes generally have a lower initial purchase cost, making them attractive for small workshops or budget-focused buyers.

Hydraulic press brakes involve a higher upfront investment, particularly CNC models, but offer advanced capabilities.

Mechanical press brakes incur higher long-term maintenance costs due to frequent mechanical wear and component replacement.

Hydraulic press brakes offer lower operating expenses, with maintenance focused on hydraulic systems and electronics.

Mechanical press brakes consume continuous power, even during idle cycles.

Hydraulic press brakes are energy-efficient, consuming power only during active bending operations.

Mechanical press brakes provide good ROI in high-volume, repetitive production environments.

Hydraulic press brakes deliver better long-term ROI for units requiring flexibility, precision, automation, and reduced rework costs.

Mechanical press brakes rely on basic safety guards, mechanical brakes, and emergency stop systems. However, the fixed stroke nature increases the risk of operator error during setup.

Hydraulic press brakes include overload protection, pressure relief valves, synchronized cylinders, and advanced safety light curtains, significantly reducing accident risks.

Mechanical press brakes require experienced operators due to limited control and manual adjustments.

Hydraulic press brakes are easier to operate, especially CNC models, with user-friendly interfaces, programmable settings, and shorter training time for operators.

Choosing between a mechanical and hydraulic press brake depends largely on your production type, material thickness, accuracy requirements, and budget.

A mechanical press brake is the right choice when:

Mechanical press brakes are commonly preferred by small to mid-scale manufacturing units focused on standardized components.

A hydraulic press brake is ideal when:

Hydraulic press brakes are widely used in modern fabrication workshops and industrial units requiring accuracy, flexibility, and safety.

Mechanical press brakes consume continuous power due to flywheel operation, even when idle.

Hydraulic press brakes are energy-efficient, consuming power only when pressure is applied during bending cycles.

Mechanical press brakes generate higher noise levels due to moving mechanical components and clutch engagement.

Hydraulic press brakes operate more quietly, creating a safer and more comfortable working environment.

Hydraulic press brakes support sustainable manufacturing by reducing energy waste, minimizing rework through precision bending, and enabling efficient material utilization.

The market is rapidly shifting toward CNC and NC hydraulic press brakes, offering programmable bending, real-time monitoring, and consistent accuracy.

Modern press brakes are being integrated with automation systems, robotic arms, and smart sensors, improving productivity and reducing manual dependency.

With growth in infrastructure, automotive, renewable energy, and manufacturing under “Make in India”, demand for advanced hydraulic press brakes is increasing across India.

Your press brake choice should align with current production needs and future expansion plans. Investing in the right technology ensures better productivity, lower waste, and higher profitability.

Which press brake is more accurate: mechanical or hydraulic?

Hydraulic press brakes are more accurate due to adjustable pressure control and CNC/NC compatibility.

Is a hydraulic press brake suitable for small fabrication units?

Yes, compact NC hydraulic press brakes are ideal for small and medium fabrication workshops.

What is the maintenance cost difference?

Mechanical press brakes generally have higher long-term maintenance due to mechanical wear, while hydraulic models require less frequent servicing.

Which press brake is better for thick metal sheets?

Hydraulic press brakes are better suited for bending thick metal sheets and heavy plates due to higher tonnage control and flexibility.

Rudraksh Engineering is a trusted name in the field of industrial machinery and engineering solutions, delivering reliable, high-performance equipment tailored to modern manufacturing needs. With a strong focus on quality, precision, and customer satisfaction, we specialize in supplying Mechanical Press Brakes and Hydraulic Press Brakes designed to meet the demands of metal fabrication industries across India.

Backed by industry expertise and a deep understanding of sheet metal processing, Rudraksh Engineering offers press brake solutions that ensure accurate bending, consistent output, and long-term operational reliability. Our mechanical press brakes are known for their robust construction, high productivity, and suitability for repetitive bending tasks, while our hydraulic press brakes deliver superior control, smooth operation, and flexibility for complex and heavy-duty applications.

At Rudraksh Engineering, every machine is selected and supplied with strict quality checks to ensure compliance with industrial standards. We work closely with reputed manufacturers to provide press brakes that combine advanced engineering, durable components, and operator-friendly designs, helping businesses improve efficiency and reduce downtime.