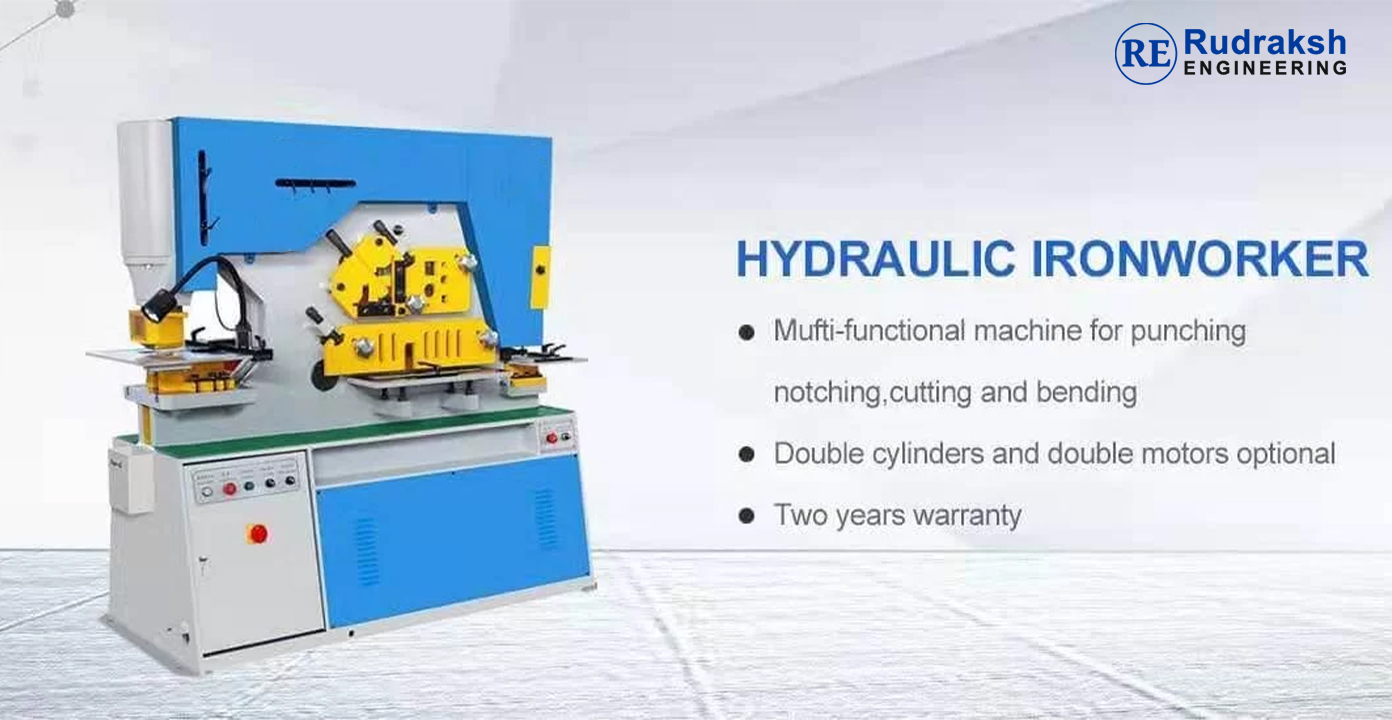

In the demanding world of metal fabrication, efficiency and accuracy define the backbone of production quality. Among the most trusted innovations in this industry is the Hydraulic Iron Worker by Rudraksh Engineering, a renowned Manufacturer and Exporter of precision-driven industrial machinery. This machine has redefined how steel, sheet metal, and structural components are processed, delivering a combination of force, finesse, and reliability that traditional press machines struggle to match.

For decades, mechanical press machines dominated metalworking floors. They provided raw force but lacked flexibility, precision, and ease of control. With the rise of hydraulic technology, the landscape transformed.

Hydraulic Iron Workers brought together multiple fabrication capabilities cutting, punching, notching, bending into a single, compact, and energy-efficient unit. Unlike conventional presses that rely on mechanical leverage, hydraulic systems operate through controlled fluid pressure, ensuring smoother operation and superior consistency across varying workloads.

Traditional press machines deliver constant force throughout the stroke, which often leads to material distortion or tool wear.

Hydraulic Iron Workers, however, regulate pressure dynamically. Operators can control tonnage according to the material type, whether mild steel, stainless steel, or alloy sheet ensuring uniformity without overloading.

This adaptability gives manufacturers the ability to process delicate parts or heavy components with the same degree of accuracy.

While a mechanical press is typically designed for one purpose, Hydraulic Iron Workers combine multiple operations like punching, notching, shearing, and bending in one machine.

Rudraksh Engineering’s designs include modular tool attachments and quick-change systems that reduce downtime during operation shifts.

This not only increases productivity but also minimizes investment in multiple machines, saving space and maintenance costs for industrial units.

Precision is the defining edge of a Hydraulic Iron Worker. Hydraulic actuation ensures linear movement without the mechanical backlash common in press machines.

The consistent pressure application throughout the stroke guarantees cleaner cuts, accurate hole punching, and burr-free edges.

Conventional press machines require manual alignment and risk higher operator fatigue or error.

In contrast, Hydraulic Iron Workers feature dual-hand operation, emergency stop controls, and hydraulic safety valves that prevent overload.

Hydraulic systems inherently experience less wear due to reduced mechanical friction.

Rudraksh Engineering enhances this advantage with industrial-grade seals, leak-resistant tubing, and easy-access maintenance points. The result: minimal downtime and predictable maintenance schedules that improve long-term productivity.

Rudraksh Engineering’s Hydraulic Iron Worker isn’t just another fabrication tool; it’s a culmination of design precision, fluid mechanics, and structural intelligence.

Each unit is engineered using high-grade steel frames, robust pistons, and precision-machined components that undergo strict quality checks before dispatch.

The machines are optimized for:

By combining these engineering elements, Rudraksh Engineering delivers machines that not only perform consistently but also maintain alignment, torque balance, and minimal heat loss — key factors that define operational excellence.

Hydraulic Iron Workers serve across multiple manufacturing sectors due to their adaptability and precision. Key application domains include:

This cross-sector compatibility makes the machine an essential investment for manufacturers looking to combine productivity and accuracy.

To understand the mechanical brilliance behind a Hydraulic Iron Worker, let’s consider its critical specification attributes that set it apart from traditional press systems:

| Parameter | Hydraulic Iron Worker | Conventional Press Machine |

|---|---|---|

| Force Application | Variable (adjustable pressure) | Fixed throughout stroke |

| Operational Modes | Multi-function (cutting, punching, notching) | Single-function |

| Accuracy Level | High, consistent stroke precision | Variable, subject to mechanical play |

| Energy Use | Controlled, load-dependent | Continuous high consumption |

| Safety System | Integrated overload & pressure relief | Limited mechanical protection |

| Maintenance | Low (fewer moving parts) | High (gear wear & alignment loss) |

| Space Requirement | Compact | Bulky |

| Output Quality | Smooth, burr-free finish | Rough, uneven cut ends |

Rudraksh Engineering refines each of these parameters through precision assembly, material quality assurance, and hydraulic efficiency — turning the machine into a reliable asset for continuous industrial operations.

As a trusted Manufacturer and Exporter, Rudraksh Engineering adheres to rigorous international standards. Every Hydraulic Iron Worker undergoes factory-level calibration and hydraulic testing before export.

The company’s strong export portfolio reaches regions where industrial automation and structural fabrication are rapidly growing — including the Middle East, Southeast Asia, and Europe.

Each exported unit reflects Indian engineering mastery — blending strength, safety, and sustainability into one cohesive machine architecture.

When industries demand efficiency and adaptability, Rudraksh Engineering delivers. The company’s Hydraulic Iron Workers excel because they are engineered with:

These elements not only enhance machine longevity but also ensure operational superiority in every production cycle.

As automation advances, hydraulic fabrication tools are integrating with CNC systems, smart sensors, and digital feedback loops.

Rudraksh Engineering is actively innovating in this direction, working on systems that combine hydraulic power with intelligent control — allowing predictive maintenance, automated pressure calibration, and IoT-based performance tracking.

The result is a new generation of Hydraulic Iron Workers that redefine what industrial precision means adaptable, efficient, and data-driven.

As a globally recognized Manufacturer and Exporter, Rudraksh Engineering stands for consistent innovation, dependable engineering, and global service support.

The company’s technical team not only provides top-quality Hydraulic Iron Workers but also ensures post-installation assistance, customization, and spare support a commitment that reflects true engineering partnership.

Q1. What operations can a Hydraulic Iron Worker perform?

A Hydraulic Iron Worker can cut, punch, notch, bend, and shear metal plates, bars, and structural profiles using hydraulic power.

Q2. How does it differ from a mechanical press machine?

It uses hydraulic pressure for controlled force application, resulting in higher accuracy, flexibility, and reduced wear compared to fixed-force mechanical presses.

Q3. Is it suitable for stainless steel fabrication?

Yes, it efficiently handles stainless steel, mild steel, and alloy sheets due to adjustable pressure and durable tooling design.

Q4. What maintenance does a Hydraulic Iron Worker require?

Regular hydraulic oil checks, seal inspections, and basic cleaning ensure long life and uninterrupted operation.

Q5. Why choose Rudraksh Engineering for Hydraulic Iron Workers?

Because the company combines precision engineering, robust construction, and global export quality standards in every machine produced.